Technology platform for a data processing company in BFSI industry.

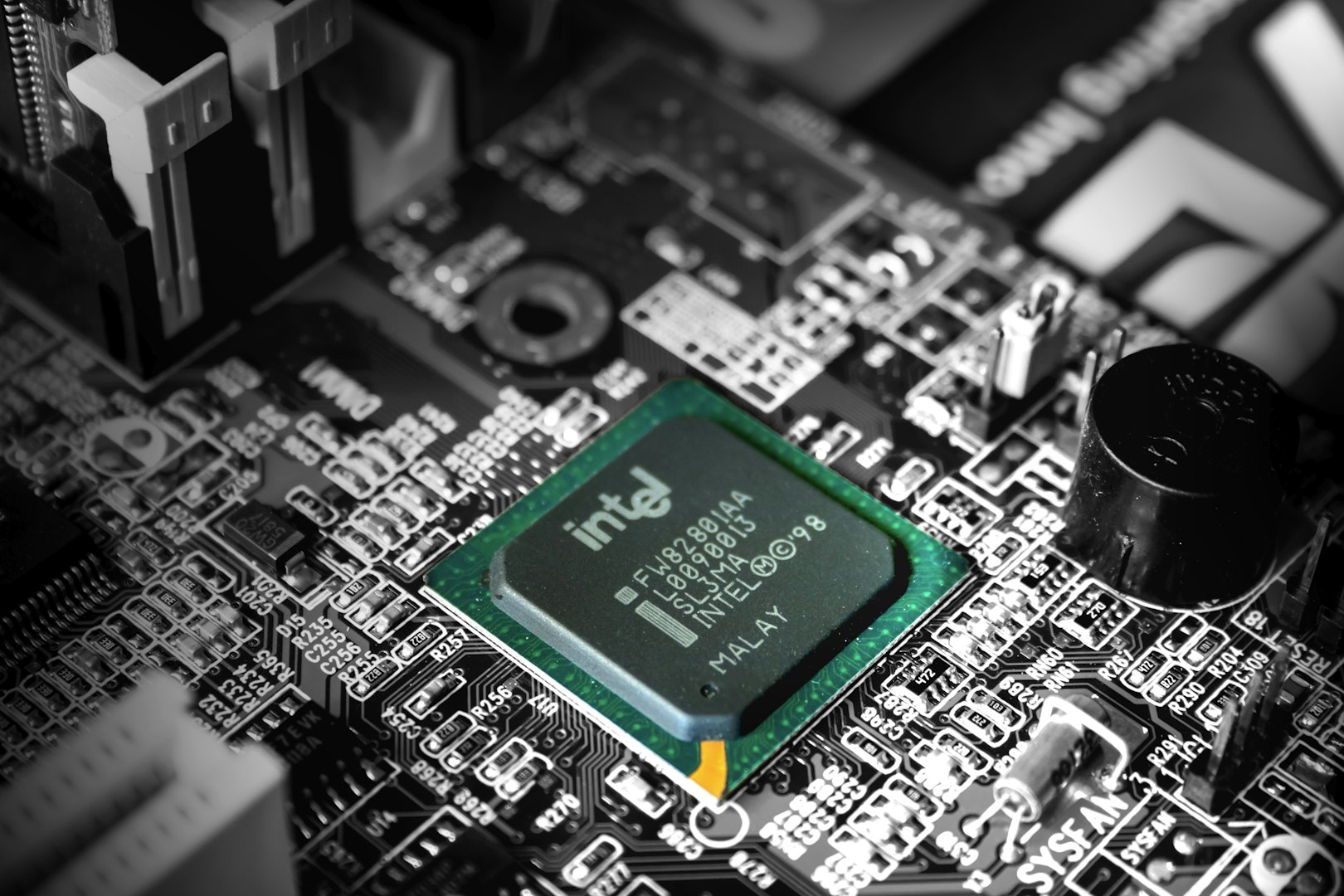

The BFSI (Banking, Financial Services, and Insurance) industry is turning to data processing automation to improve efficiency and customer service. AI, machine learning, and edge computing are driving digital transformation for personalized, secure services. Challenges like latency, network congestion, and security concerns are being tackled for successful technology deployment. With a significant increase in IT spending, the future of BFSI operations will be shaped by advancements in automation and digital processes.