Digital Technologies for Manufacturing

Advanced technology and robust software development capabilities for seamless implementation of Digital Manufacturing - Industry 4.0, leveraging the Industrial Internet of Things (IIoT), and integration with ERP and MES systems.

PVMs technological innovations are not only enhancing productivity but are also fostering a more agile workforce and revolutionising the concept of a smart factory.

As industries continue to adapt to the demands of a digital age, investing in these smart technologies is crucial for staying competitive and achieving operational excellence!

Digital Manufacturing Technologies - Industry 4.0

Industrial Internet-of-Things (IIoT)

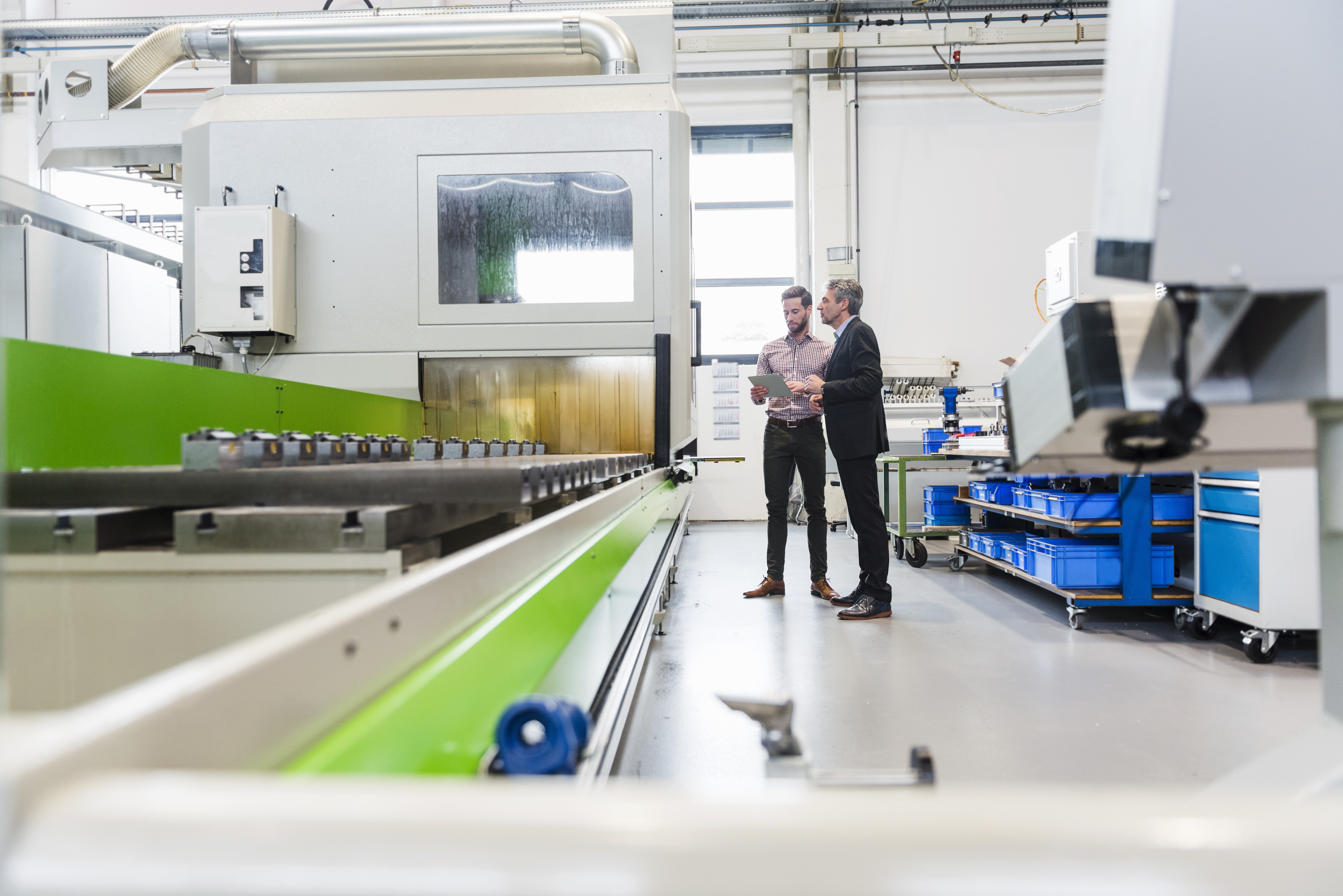

Smart Workforce - Digital Work Instructions

Digital Twins

Control Automation

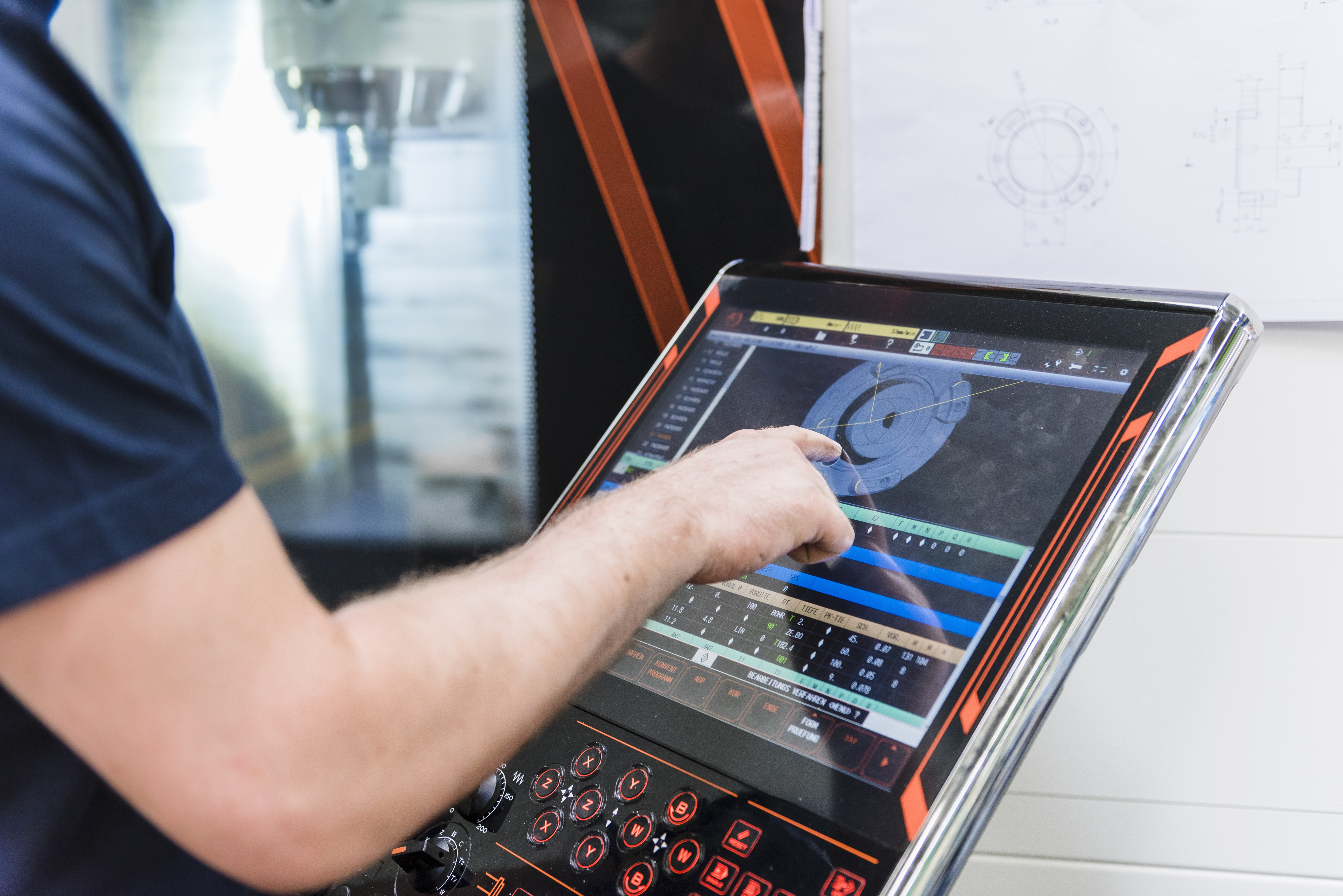

OPC UA and PLC integration

HPC and Edge Computing

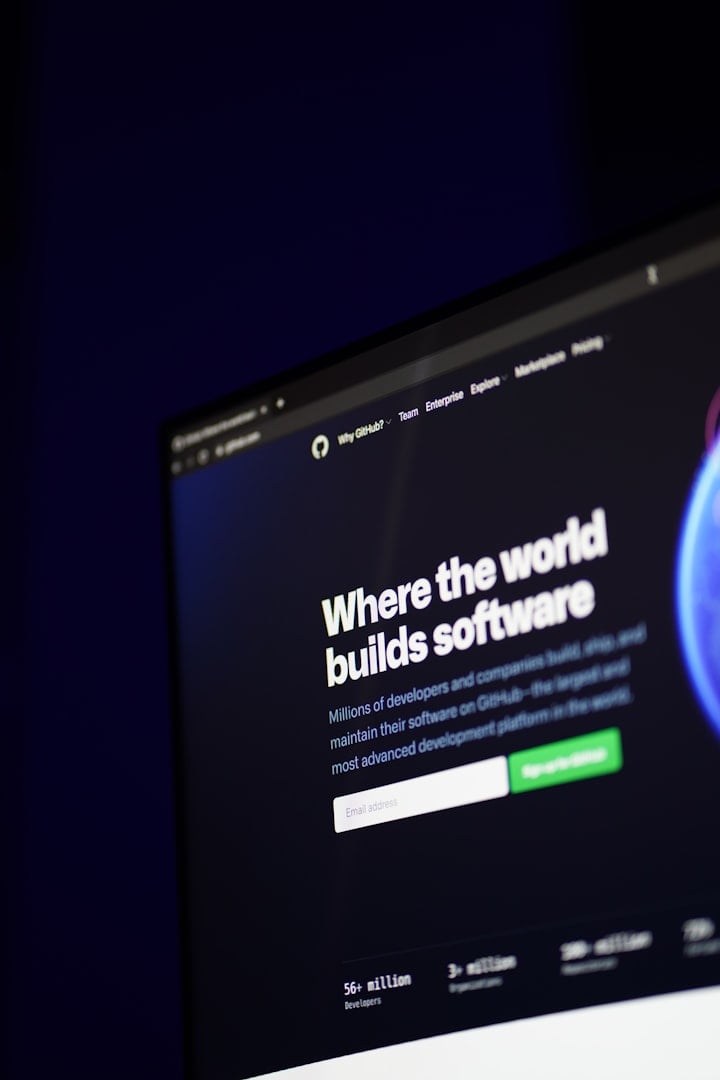

Platform Technologies

Embedded Systems

Enterprise Systems Integration

AR VR for industrial use

Cyber Security in Industrial Applications

ERP and MES integration